Custom Molding.

Family-Run Precision.

With 15+ years of combined experience and a commitment to hands-on service, Shiloh Custom Molding delivers high-quality rotational molding for a wide range of industries. As a family-owned company, we prioritize craftsmanship, streamlined operations, and long-term partnerships with every client.

From Production to Fulfillment.

We Handle It All.

From raw resin to finished, shipped product, our team manages every step with care. Whether you're scaling production or need consistent surface finishes, we deliver reliable, competitively priced solutions backed by personalized support.

Custom Molding & Full-Service Solutions

From precision rotomolding to finishing and drop shipping, we provide streamlined manufacturing services designed to meet your product goals from start to final delivery.

Frequently Asked Questions

Have questions about our molding process, surface finishing, or drop shipping options? Explore our FAQ section for quick answers to help guide your next custom project with us.

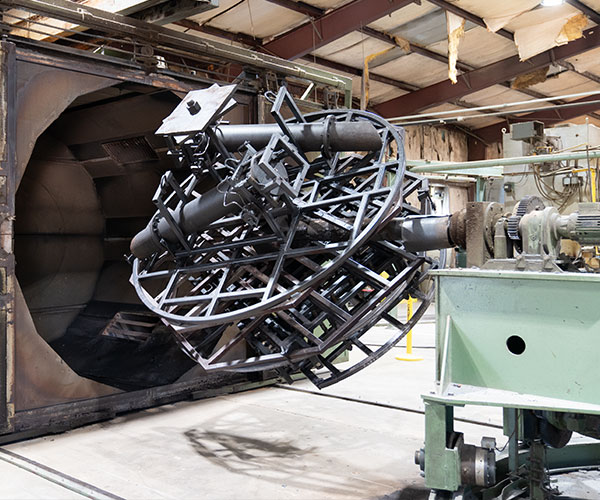

Rotational molding, or rotomolding, is a process used to create hollow plastic parts by heating and rotating a mold. It produces seamless, durable components with even wall thickness.

Industries We Service

We work with companies across diverse industries to deliver durable, high-quality molded parts. From automotive to agriculture, we tailor our process to meet your exact needs.

Serving a Diverse Range of Industries

Shiloh Custom Molding partners with companies across a wide range of industries to deliver high-quality, custom-molded plastic components. From rugged industrial housings to sleek consumer products, we understand that each sector has specific performance demands, durability standards, and design challenges. Our team works closely with clients to tailor each part to its real-world application—ensuring functionality, consistency, and visual appeal.

Built for Strength, Precision & Reliability

Whether producing impact-resistant enclosures for agricultural equipment or ergonomic parts for consumer use, we bring specialized knowledge and hands-on care to every project. Our rotational molding process, combined with custom surface finishing and drop ship fulfillment, allows us to serve sectors where durability, efficiency, and aesthetic quality all matter. No matter the industry, we’re built to deliver dependable results—part after part, shipment after shipment.

Automotive

Industrial Equipment

Medical & Dental

Consumer Products

Agriculture

Marine

Construction

Electronics

News & Articles

Explore expert tips, company updates, and industry insights in our blog—designed to keep you informed on all things rotational molding, product development, and logistics.